About Mission Patterns

At the core of Mission Patterns expertise is a firm foundation in those traditional skills upon which pattern & mould making is based.

More than 50 years of learning the business from the ground up and an ability to handcraft with precision now combine with the latest technologies and manufacturing processes in a company which retains and respects traditional skills but has a very modern outlook.

With an ability to respond quickly without ever compromising quality, Mission Patterns is clearly customer-focused – and has a firm grasp upon the requirements of clients who are often under deadline pressures.

We can follow a project through from initial concept to production prototype and have experience across a broad spectrum of businesses, industries and projects – from small quantity foundry castings to design, engineering and supply of complex patterns for the construction and utilities-based industries, to production of stone moulds for the architectural applications…

The well-equipped workshop is in Dronfield, Derbyshire, within easy reach of the M1 motorway (Junctions 29 & 30) and we are ideally located to service customers throughout the Midlands.

Whatever the project, whatever the industry, it’s our mission to build strong customer relationships based upon delivering exceptional quality and expertise – we aim to be a supplier who exceeds your expectations – and one you trust to get the job done.

Engineering Patterns and Moulds

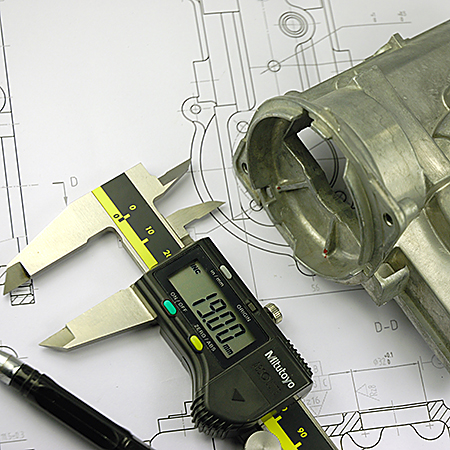

Mission Patterns offers a comprehensive range of skilled manufacturing processes for engineering pattern making, CNC tooling, modelling and mould making, using the latest materials and technologies to meet the requirements of a wide range of the industries and sectors.

A keen eye for detail, and exceptional accuracy and care combine to ensure impressive results across a wide range of projects.

Typical projects include manufacturing CNC cut patterns and tooling, traditional patterns made from 2D drawings, reverse engineering castings using the 3D scanning technology and our traditional skills, CAD modelling, and precast mould making for the refractory and concrete industries.